(A) Used with hydraulic:

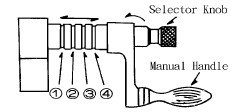

- Pull out the selector knob (Omit this step, the hydraulic mechanism was well adjusted by factory).

- Set the lock pin according to the size of the workpiece (6 ranges jaw opening).

- First, turn the handle to fasten the workpiece.

- Apply a slight shock to the handle and knock lightly by hand (Shift the power source to hydraulic mechanism). Increase the clamping force according to the demand of the work, and you can accomplish fine adjustment of clamping force, using the base line (1) (2) (3) (4) as a guide:

(1). ca. 2000 — 3000 KGS

(2). ca. 3000 — 4000 KGS

(3). ca. 4000 — 5000 KGS

(4). ca. 5000 — 6000 KGS

- Released easily by turning the handle counterclockwise。

(B) Used without hydraulic:

By pushing the selector knob in the normal position (non hydraulic system)

CAUTIONS FOR USE

- Don’t hit the handle with a hammer, while fastening.

- Don’t let vise open too much.

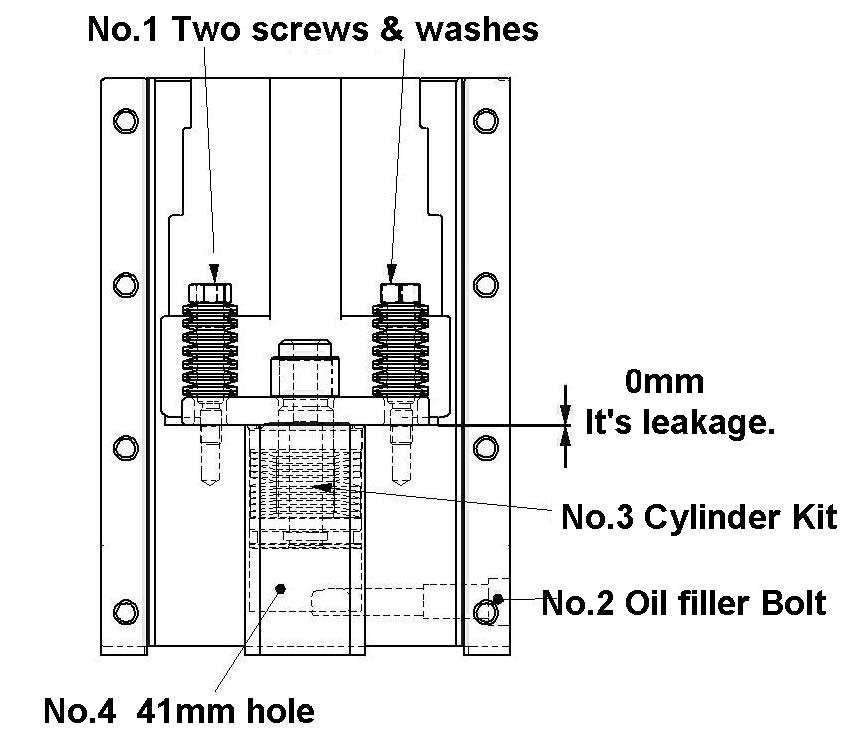

- The clamping force will be reduced if oil quantity reduced.

- #140 or other similar oil is used. Don’t let air enter the hydraulic chamber.

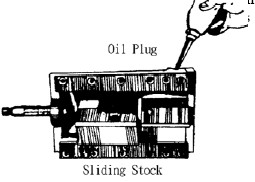

Method of oil supply: separate the sliding stock from the base. Remove the oil plug, pour oil in and tighten the plug, then the replenishment is done.